Types of Gloves

Types of Gloves Explained – Nitrile, Latex, Vinyl

Protection against contact with hazardous materials is important for everyones health and safety.

Work and job sites often have many chemicals, substances or materials that can cause skin damage and/or provoke allergic reactions. In fact some toxic chemicals can be slowly absorbed through the skin and into the bloodstream. Skin can become damaged, irritated and even broken by friction or from extremes of heat. In biological work, skin contamination can lead to infection.

All of these facts are reasons why it is super important that you understand all the types of gloves and which glove you specifically need to protect yourself. It is important to remember that given the wide range of work being done no single glove will meet the needs of everyone. Gloves must be selected on the basis of the materials being handled and the type of work undertaken.

Considering there are so many types of gloves available on the market, it can be very confusing as to which type of glove is best suited for your application.

So let’s review the various glove types, materials, safety considerations and test ratings/standards as a first step:

Disposable Gloves or Re-useable Gloves

Glove Materials (eg Nitrile Gloves, Vinyl Gloves, Latex Gloves, Neoprene, Butyl Rubber, Viton)

Glove test ratings/standards – what EN test standards are required?

(see The Glove Information Page for more details)Incidental Contact vs Intentional Contact with hazardous substances or situations

Disposable Gloves vs Re-usable Gloves

Disposable gloves are thin, generally 101 – 202 microns thick. This allow the user to retain good touch sensitivity and dexterity but they have poor chemical resistance. They are designed to protect against incidental rather than intentional contact with chemicals and should be changed after any splash. They are designed for single use only and should never be re-used.

Disposable gloves are not suitable for handling some aggressive or highly hazardous chemicals. They provide little useful protection against physical hazards as they may easily tear or puncture if snagged.

Re-usable gloves are 457 – 711 microns thick. They offer greater protection than disposables against abrasion and other physical hazards, are less likely to tear in use and wil resist chemical attack for longer. However, they interfere more with dexterity and touch sensitivity and may still be damaged or penetrated by many chemicals. They need to be looked after to prolong their usefulness. Re-usable gloves usually have a longer cuff length than a disposable glove made with the same material and so offer better protection against liquid dripping over the top of the glove.

Care of reusable gloves – Re-useable gloves need to washed and dried after work to avoid accidental skin contamination when next putting the gloves on. This is especially important if the work has involved immersion or handling of chemicals that can permeate the glove material. If frequently re-used the gloves should periodically be turned inside out and the inner surface washed and rinsed off. Re-useable gloves should be inspected before each use for discoloration, cracking at flexion points or damage and should be discarded if found. They must also be discarded if the inside becomes contaminated.

Incidental Contact vs Intentional Contact

Incidental contact refers to tasks where there is no intended direct contact with the hazardous material. Exposure will only occur through a splash or spill. Most types of disposable gloves can provide adequate protection provided that when they are used to protect against chemical hazards, they are changed immediately after a splash or spill occurs.

Intentional contact refers to tasks where contact with the hazardous material is inevitable e.g. immersing hands in liquids, direct handling of a substance rather than its container or handling of materials coated or saturated with the hazardous substance(s) e.g. a cleaning rag. There is therefore relatively lengthy contact with significant amounts of the hazardous substance. When selecting a glove for protection against intentional contact with chemicals, it is necessary to select a glove made from a material that offers good resistance to attack or permeation from the specific chemicals in use. This will often require a reusable glove.

Cut Rated Gloves

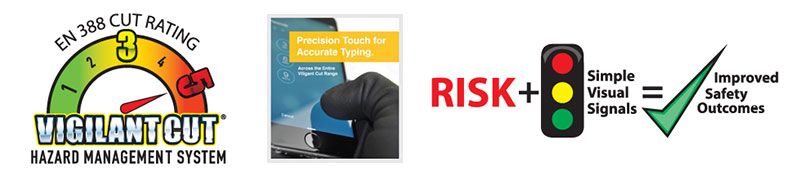

Cut Rated gloves have been tested under the EN388 Gloves Standards which measure protection against risks such as Abrasion, Cut, Tear and Puncture. In many industries, Cut Rated gloves are mandatory under Occupational Health & Safety regulations and must be worn at all times.

Learn more about the importance of Cut Rated gloves by viewing the Komodo® Vigilant Cut Hazard Management System where Cut Rated Gloves are manufactured in Hi-Vis colours, linking hazards and tasks with Hi-Vis colours to ensure compliance.

In many industries, Cut Rated gloves are mandatory under Occupational Health & Safety regulations and must be worn at all times. Learn more about the importance of Cut Rated gloves by viewing the Komodo® Vigilant Cut Hazard Management System where Cut Rated Gloves are manufactured in Hi-Vis colours, linking hazards and tasks with Hi-Vis colours to ensure compliance.

Cut Rated Gloves

Nitrile

- Good for solvents, oils, greases, hydrocarbons and some acids and bases

- Good alternative to latex for biochemical work

- Clear indication of tears or breaks

- Avoid: intentional contact with ketones, oxidizing acids and organic compounds containing nitrogen

- Nitriles are the best choice for splash protection against chemicals

Chloronite® New Material Technology

- Chemical resistant materials have been combined in the past, with mixed results.

- Now, the co-polymer design of the Chloronite® material brings together a sophisticated formulation of Soft Nitrile and Neoprene.

- This development has produced a Chloronite® material that is powerfully resistant to a very wide range of EN recognised chemicals.

Chloronite® New Material Technology

- Chemical resistant materials have been combined in the past, with mixed results.

- Now, the co-polymer design of the Chloronite® material brings together a sophisticated formulation of Soft Nitrile and Neoprene.

- This development has produced a Chloronite® material that is powerfully resistant to a very wide range of EN recognised chemicals.

Butyl Rubber

- Good for ketones and esters

- Poor for gasoline and aliphatic, aromatic and halogenated hydrocarbons

- Expensive

- Only available as re-usable

- Poor touch sensitivity

Polyvinyl Chloride (PVC) – Standard Vinyl Gloves

- Good for acids, bases, oils, fats, peroxides and amines

- Good resistance to abrasions

- Poor for most organic solvents

- Plasticisers in glove may contaminate solvents

- Avoid: intentional contact with keytones, oxidizing acids and organic compounds containing nitrogen

- Inexpensive

- The best choice for protection against soiling, low hazard chemicals or food hygiene use

Vinyl – Polyvinyl Alcohol (PVA)s

- Chemical resistant materials have been combined in the past, with mixed results.

- Now, the co-polymer design of the Chloronite® material brings together a sophisticated formulation of Soft Nitrile and Neoprene.

- This development has produced a Chloronite® material that is powerfully resistant to a very wide range of EN recognised chemicals.

Neoprene

- Good for acids, bases, alcohols, fuels, peroxides, hydrocarbons and phenols

- Poor for halogenated and aromatic hydrocarbons

- Often associated with wetsuit material

Viton

- Good for chlorinated and aromatic solvents

- Low surface tension repels most liquids

- Good resistance to cuts and abrasions

- Poor for ketones

- Expensive and uncommon

- Only available as re-usable

- Poor touch sensitivity